Makswell Makine Gıda Medikal Ltd. Şti., as manufacturer of quality control equipments produces special devices for grains, feed, wheat and flour laboratories and exports to 38 different countries. Our company, which stands out in the sector with its experienced staff and wide product range, develops easy-to-use and customizable devices that meet quality control needs.

İvedik OSB Mah. 1514. Cadde, No:3 Yenimahalle, Ankara, Turkey

+90 312 395 67 37

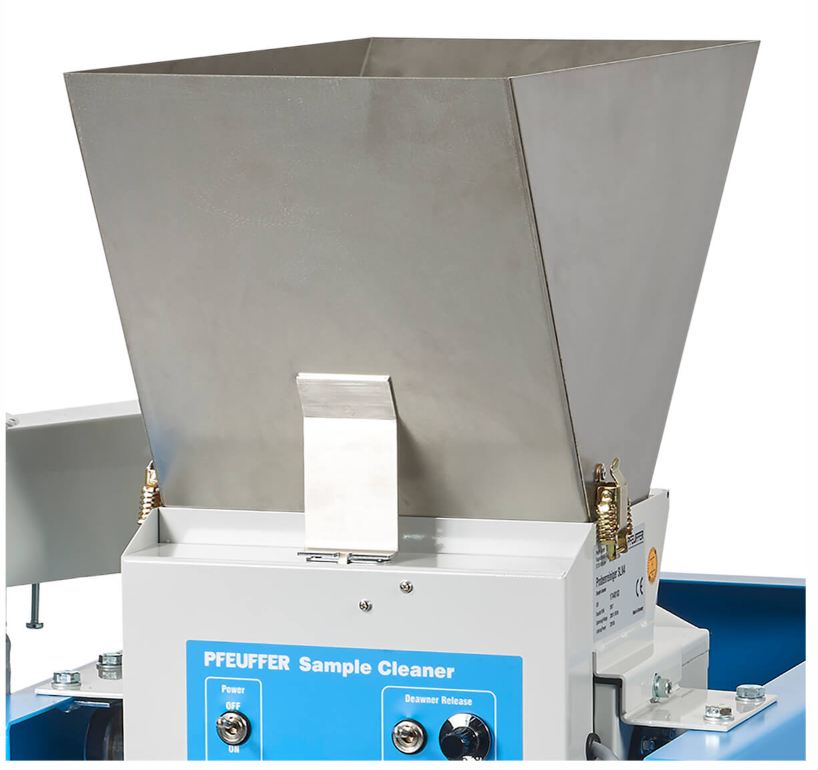

The proportion of impurities (coarse particles, fine particles, aspiration discharge) and the proportion of quality grain can be determined directly upon receipt using a sample. This makes it possible to accept quality grain and reject batches that do not fulfill the contractual conditions in a targeted way.

Fully automatic cleaning

With deawner and aspiration

Quick sieve change

Additional sorting sieves for sorting out shriveled and small grain

Sorting sieve system with cleaning balls

Put in sample and start the cleaning process. If necessary, the sample is first deawned for a preselectable time. Then the deawner opens automatically and the sample falls through the aspiration chamber. The lightweight dirt is extracted by the aspiration and deposited in the dust bag by the cyclone. The sample runs over the straw sieve, which removes bigger impurities and then runs over the sand sieve. Sand and small impurities fall through the sand sieve. The sample is finally led through the sorting sieve (model SLN4 = 2 sorting sieves). Rubber balls prevent the sorting sieve from clogging. The impurities run into the side collection pan. The shriveled and small grain is collected in the left-hand tray and the quality grain in the right-hand tray.