Makswell Makine Gıda Medikal Ltd. Şti., as manufacturer of quality control equipments produces special devices for grains, feed, wheat and flour laboratories and exports to 38 different countries. Our company, which stands out in the sector with its experienced staff and wide product range, develops easy-to-use and customizable devices that meet quality control needs.

İvedik OSB Mah. 1514. Cadde, No:3 Yenimahalle, Ankara, Turkey

+90 312 395 67 37

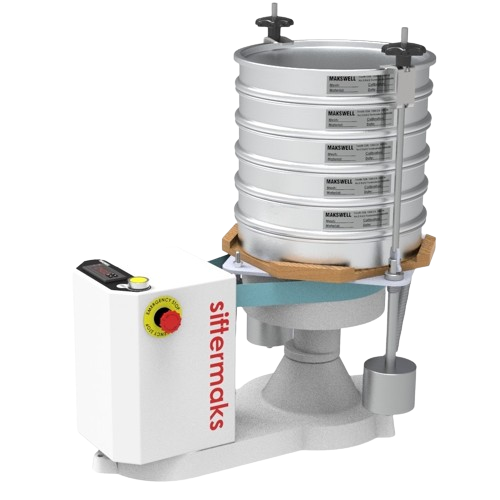

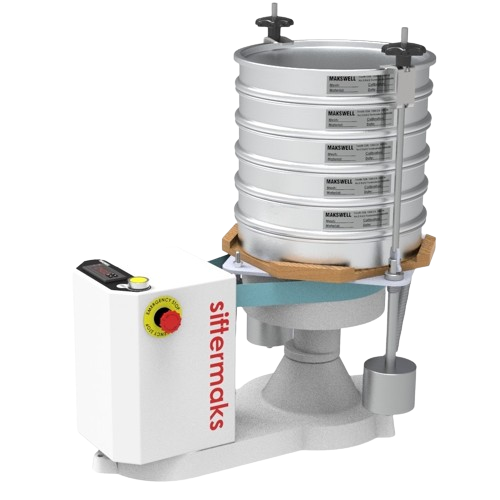

Siftermaks, a laboratory-scale sieve shaking device, is used to classify the grain size of wheat flour. It has a circular sieving feature for better and more efficient sieving. The sieves are placed in such a way that their pore sizes decrease from top to bottom. After the sifting process, the sieves are removed and the amount remaining on each sieve is weighed and the percentage is calculated.

• Circular working system for more efficient screening

• Five Aluminum pulleys are provided as standard

• Pulley capacity can be maximum 7 pieces

• Main body weighted with steel casting

• Possibility of fixing to the ground for user safety

Sieve Dimensions: Possibility of using polyester sieves between 90 and 1400 microns

Safety: emergency stop button for safety purposes and protection sheet for the engine with belt

Digital Control Unit: Time can be adjusted from 0 to 99 minutes with the control unit with 4-digit LED display

There are various methods and techniques for determining the grain size distributions of materials. The easiest and most widely used among these is the "Sieve Analysis Method", which is done with laboratory sieves. The concept of "mesh number" is used when the sieves used in the sieving process are classified according to their size. The sieving process can be done manually or automatically. In manual sieving, sieves are used one by one. In automatic sieving, a sieve shaking device is used. The sieve set, prepared by placing the sieves on top of each other so that the sieve openings become smaller from top to bottom, is tightly placed on the sieve shaking device. The device moves the sieves in the form of continuous vibration + elliptical rotation + pulse. At the end of the sifting process, the sieves are removed, the amount remaining on each sieve is weighed, and the weight percentage of that grain size is calculated in proportion to the total amount of material. The results obtained are evaluated graphically.